Description

The 3500/22M Transient Data Interface (TDI) is the interface between the 3500 monitoring system and compatible software (System 1 Condition Monitoring and Diagnostic software and 3500 System Configuration software). The TDI combines the function of a 3500/20 Rack Interface Module (RIM) with the data collection capability of a communication processor such as TDXnet.

The TDI resides in the slot adjacent to the power supplies of a 3500 rack. It interfaces with M series monitors (3500/40M, 3500/42M, etc.) to continuously collect steady state and transient dynamic (waveform) data and pass this data through an Ethernet link to the host software. Refer to the Compatibility section at the end of this document for more information.

Static data capture capability is standard with the TDI. However, using an optional Channel Enabling Disk will allow the TDI to capture dynamic and high-resolution transient data as well. The TDI incorporates the communication processor function within the 3500 rack

Although the TDI provides certain functions common to the entire rack, it is not part of the critical monitoring path and has no effect on the proper, normal operation of the overall monitor system for automatic machinery protection. Every 3500 rack requires one TDI or RIM, which always occupies Slot 1 (next to the power supplies).

I/O Module Signal Common Terminal

Both versions of the TDI I/O Module now include a 2-pin connector for connecting Signal Common to a single point Instrument Ground for the rack. When this is done, the selector switch on the side of the Power Input Module (PIM) must be slid in the direction of the arrow marked “HP” to isolate Signal Common from chassis (safety) ground.

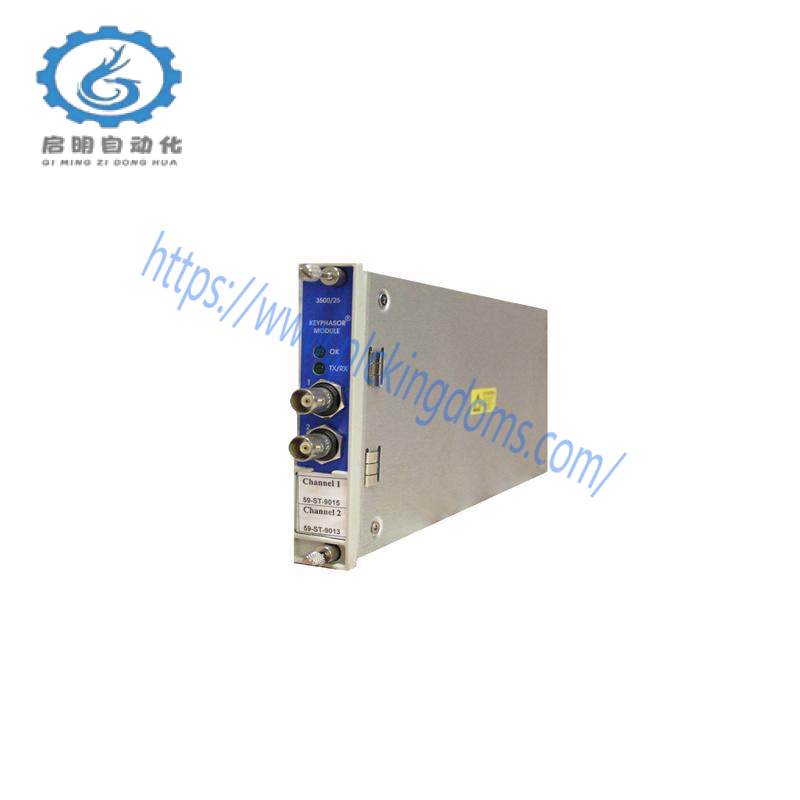

Keyphasor Inputs

Supports the four 3500 system Keyphasor signals. The speed range support is based on the number of dynamic channels enabled:

Supports multiple events per revolution speed inputs up to 20 kHz

Startup/Coastdown Data

Data collected at selected increments of speed and time

Increasing and decreasing speed intervals are independently programmable

Initiation of transient data collection based on detecting the machine speed within one of two programmable windows

The number of transient events that can be collected is only limited by the available memory in the module

Alarm Data Collection

Pre- and post-alarm data

Static values collected at one second intervals for 10 minutes before the event and 1 minute after the event

Static values collected at 100 ms intervals for 20 seconds before the event and 10 seconds after the event

2.5 minutes of waveform data collected at 10-second intervals before the alarm and 1 minute of waveform data collected at 10-second intervals after the alarm

Static Values Data

TDI will collect the static values including the values measured by the monitors.

TDI provides four nX static values for each point. Amplitude and phase are returned for each of the values.

Waveform Sampling

Collection of waveforms for 48 channels.

DC-coupled waveforms

Simultaneous Synchronous and Asynchronous data sampled during all operational modes

User-configurable Synchronous waveform sampling rates:

o 1024 samples/rev for 2 revolutions

o 720 samples/rev for 2 revolutions

o 512 samples/rev for 4 revolutions

o 360 samples/rev for 4 revolutions

o 256 samples/rev for 8 revolutions

o 128 samples/rev for 16 revolutions

o 64 samples/rev for 32 revolutions

o 32 samples/rev for 64 revolutions

o 16 samples/rev for 128 revolutions

Asynchronous data sampled to support an 800-line spectrum at the following frequency spans:

quency spans:

o 10 Hz

o 20 Hz

o 50 Hz

o 100 Hz

o 200 Hz

o 500 Hz

o 1000 Hz

o 2000 Hz

o 5000 Hz

o 10 kHz

o 20 kHz

o 30 kHz

Asynchronous data is anti-alias filtered

Channel Pairs for providing Orbit or synchronous full spectrum presentations can be split among multiple monitors. For asynchronous full spectrums the channels must be within a monitor channel pair (30 kHz frequency span data will not be phase correlated between channel pairs)

1. Main Module

2. 10 Base-T/100 Base TX (copper) Ethernet I/O Module

3. 100 Base-FX (fiber optic) Ethernet I/O Module

4. LEDs indicate operating status of the module

5. Hardware Switches

6. USB Configuration Port for configuring or retrieving

machinery data

7. OK Relay indicates the OK status of the overall rack

8. Signal Common external grounding terminal

9. RJ-45 Ethernet Port for configuration and data collection

10. System Contacts

11. Fiber Optic Ethernet Port for configuration and data collection

Related product recommendations:

Bently Nevada 3500/40M-03-00

WOODWARD EASYGEN-3500-5/P2 8440-2145

BENTLY 3500/92 136180-01

Baumuller BKD6/070/460-235000R00

Bently 3500/03 129131-01

Bentley 3500/45

BENTLY 3500/70M 176449-09

ABB 89NG03 GJR4503500R0001

Bently Nevada 3500 176449-01U

Bently 3500/22

Bently Nevada 3500/40M 176449-01

Bently 3500/94

Bently Nevada 3500/65-01-01

BENTLY 3500/32 125712-01

Bently Nevada 3500/20

Bently Nevada 3500/42-04-01

More…

Leave a comment

Your email address will not be published. Required fields are marked *